+48 95 762 08 61

Modern technologies of metal working

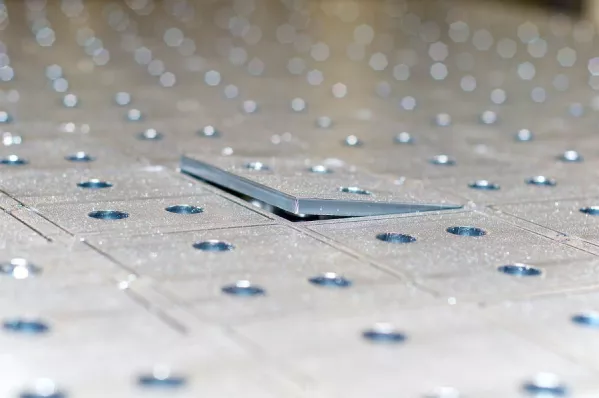

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser is a device which emits electromagnetic radiation within the range of visible spectrum, infrared and ultraviolet. The name „laser“ is an acronym for Light Amplification by Stimulated Emission of Radiation which is the phenomenon used in this device. This radiation is coherent, polarised, and it has very small divergence.

A laser comprises: an optical resonator, active medium and pumping system which pumps energy into the active medium. Laser action, i.e. quantum amplification (multiplication) of photons , occurs in this medium. The role of the optical system is selection of relevant photons.

The most important properties of laser light are:

Laser is increasingly used in industry, including also metalworking. Laser cutting is a modern method used by plants in the metal industry. In our plant, we also use the best method of laser cutting, that is cutting by means of a laser cutter. This method is compared to classic metalworking , but the cutting element is a laser beam or high-purity technical gas. Argon, nitrogen or active gas in the form of compressed air or oxygen are most commonly used. The whole process of laser cutting depends on the absorption of radiation and thermal conductivity of materials. The absorption coefficient depends, among others, on the material, condition of the surface of a cutted material as well as temperature.

Our company recommends metal cutting services of the highest quality rendered by means of the newest Trumpf laser cutting machine with Fiber source and TruDisk laser power of 6kW. The full offer of laser cutting services is available on our website in „offer – laser cutting“ section.

More information on our services can be obtained in our company’s seat in Strzelce Krajeńskie, ul. Cmentarna 4, or under the following telephone number: +48 95 762 08 61.

We recommend our laser cutting services.