+48 95 762 08 61

Modern technologies of metal working

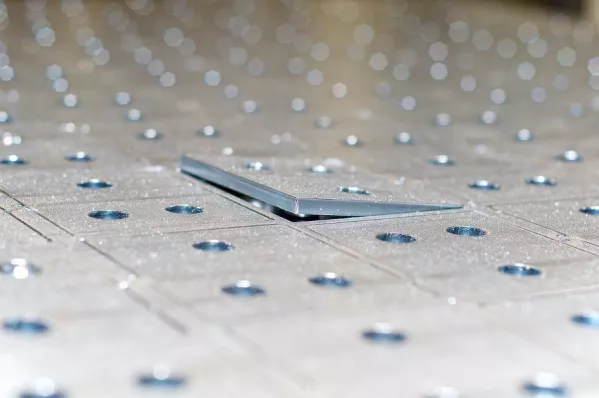

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Cutting various materials forces companies to invest in the latest technologies. Traditional methods are not very efficient and require commitment of many persons. Traditional methods of cutting, among others, plastics, include machining. To date, it was one of the most frequently used cutting methods. To be effective, it requires a sharp cutting tool and high speed. However, milling creates a risk of damage to the structure of the material or a cutting tool which results in the damage of the material. What is more, one must control efficiency of their machines.

Manual cutting may be carried out using such tools as: blades, saws, diamond planers, scissors, bandsaws or cutting machines. These tools are used mainly to cut single objects. Unfortunately, they also have disadvantages such as loudness, large quantities of dust generated during cutting, lack of cutting precision.

The situation is different when it comes to the use of laser, a modern cutting method. High precision, quickness of operation and repeatability are the most important features of laser technology. Currently, it is a cutting method used most frequently by metal plastic forming plants. Laser definitely has more advantages than disadvantages, that is why it is so popular. Laser cutters, mainly those which are numerically controlled, significantly reduce cutting time, lowering at the same time production costs. What is more, laser cutting makes it possible to cut small details of any shape in inaccessible places.

Our company recommends the latest laser cutting technology. On our website you can read more about our latest laser cutter.

We invite enterprises from the country as well as abroad to closely cooperate with us in the field of laser cutting. We provide detailed information under the following telephone number: +48 95 762 08 61.

We recommend it.