+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

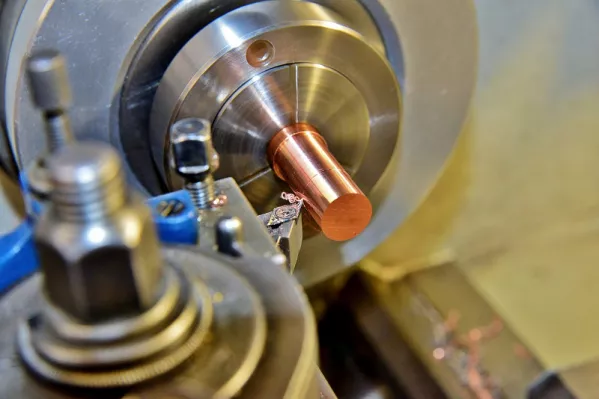

The turning process consists in machining the inner and outer surfaces of the material in the shape of rotating solids. The final result is an item with the required shape and dimension. The machines used for turning are called lathes and the person who separates the excess material with a lathe knife is called a turner.

CNC machining means turning using machines integrated with a computer, which translates into speed, precision and efficiency of the process. CNC turning is very often used in batch production, when it is necessary to make large quantities of components with identical appearance. Therefore, it is required to design the entire turning process individually and then programme it. This will make the production more cost-effective, and thus price-competitive, at a later stage. CNC turning for any plant means a continuous production cycle with optimum productivity and material savings.

For the CNC turning process, we use the latest generation of numerically controlled lathes, which allow us to produce a wide variety of parts and high volumes. Furthermore, numerical control allows us to guarantee repeatability of parts to all our customers while maintaining competitive prices. Please visit our website to see our full CNC turning offer in the offer tab.

For more information about our CNC services, including turning and milling, please contact us on +48 95 762 08 61.

We recommend CNC turning.