+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

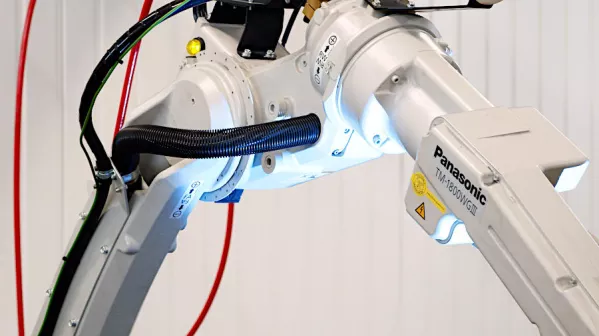

The Panasonic TAWERS TM 1800 WG3 welding robot is an extraordinary device in our facility, which we use for welding various materials, including low-carbon steel, stainless steel, and aluminum. Above all, we use our welding robot for welding using the MIG/MAG and TIG methods.

MIG/MAG Welding

MIG/MAG welding is welding with a consumable electrode under a shield of inert (MIG, 131) or active (MAG, 135) gases. Inert shielding gases use argon or helium, and active shielding gases use carbon dioxide or a mixture of carbon dioxide with argon. The method s name is derived from the English names: MIG - Metal Inert Gas, MAG - Metal Active Gas.

Welding with this method involves supplying the welding wire with electric current, which melts the welding wire as well as the surface of the material being welded. Our Panasonic TAWERS TM 1800 WG3 welding robot is equipped with MAG welding torches, which are used for welding low-carbon and stainless steel. Thanks to them, it can achieve very high welding speeds, as well as high-quality welds. Hence, there is a significant interest from the aerospace and automotive industries.

MIG/MAG welding is one of the most widespread methods. It has many advantages and a few disadvantages. The most important advantages include:

Among the disadvantages, we can include welding spatter, especially under the shield of carbon dioxide (MAG), the tendency for adhesion in welded joints or during manual welding, and the quality of the welded joint is strongly dependent on the skill of our welder.

TIG Welding

TIG welding involves supplying an electric arc between the TIG electrode and the material being welded. It is most commonly used for welding aluminum. The welding robot has the capabilities to use TIG welding torches. These torches are equipped with special arc control systems, which translates to precise control over the welding process.

If you are looking for the best welding method using our welding robot, please contact us at +48 95 762 08 61.