+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

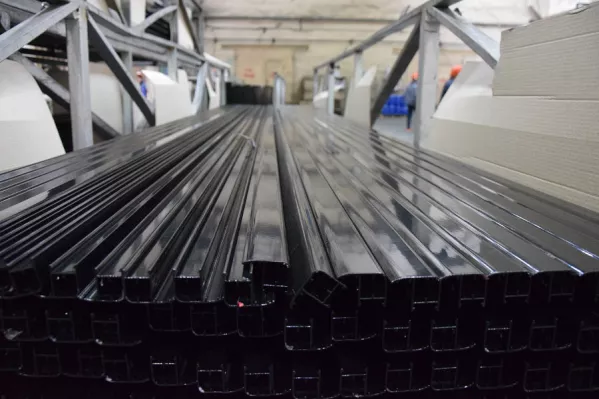

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Aluminium belongs to light metals, and it is exceptionally malleable. What is more, it is characterised by good electrical and thermal conductivity as well as high corrosion resistance. Aluminium is used mainly in aeronautics and transport industry as well as in window and door production.

Aluminium is plastic – it is subjected to rolling, cold extrusion and hot extrusion. The aforementioned thermal conductivity may be reduced by contamination by iron, zinc, copper, silicon and titan. These elements reduce conductivity, but they increase strength and hardness of aluminium.

Aluminium alloys are obtained by melting aluminium with a metal or non-metal, so as to enable them to acquire appropriate characteristics. Obtained alloys have properties worse than the aluminium itself. That is why alloys reaching the best parameters for heat treating are used. Aluminium alloys are divided into the following alloys:

Alloys for plastic forming usually contain less alloying additives such as copper, manganese and magnesium. Zinc, silicon, nickel and chrome are rarely added. The example of aluminium alloys are fechral (chromal), that is iron, chrome and aluminium alloy, as well as kanthal, that is iron and chrome alloy with an addition of a small amount of aluminium and cobalt.