+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Modern machines have replaced traditional equipment such as guillotine shears, knives and saws in the cutting process. The reason for this is that there is a very high demand for further processing of the workpiece. Therefore, they sometimes serve rather as auxiliary tools.

Nowadays cutting processes involve the latest technologies such as:

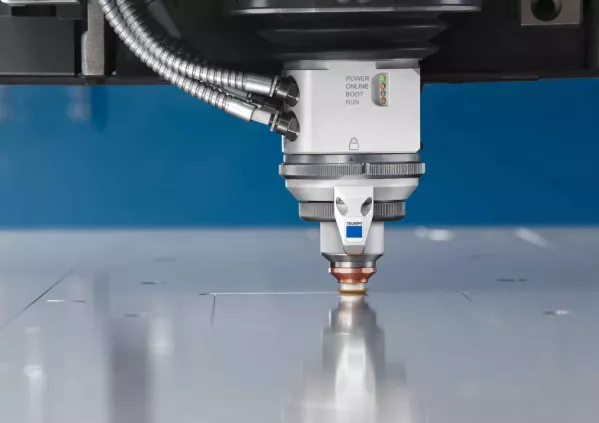

In the metalworking industry, the most popular method is laser cutting, which is mainly used to cut steel of different types and thicknesses. Among the laser cutters, the most popular are fibre lasers, but still some companies work with CO2 lasers. Some manufacturers of laser cutting machines take the easy path by installing fibre laser sources in their old cutting machines.

The market of cutting machines is constantly evolving, offering more powerful, faster and more efficient machines. Moreover, automation further encourages the constant control of the entire cutting process without the involvement of a large number of workers. The use of advanced cutting machines allows companies to reduce labour costs, quickly process ever increasing orders and, above all, increase productivity. The growing competition also contributes to the implementation of such solutions.

In our plant, we also use a modern Trumpf laser cutting machine with Fiber source with 6 kW TruDisk laser, which is increasingly streamlining the processing of orders from both domestic and foreign markets.

We invite you to check out our laser cutting offer via our website. And for more detailed technical information, please call +48 95 762 08 61. Please feel free to submit your inquiries via email: poczta@prometalform.eu

We recommend laser cutting.