+48 95 762 08 61

Modern technologies of metal working

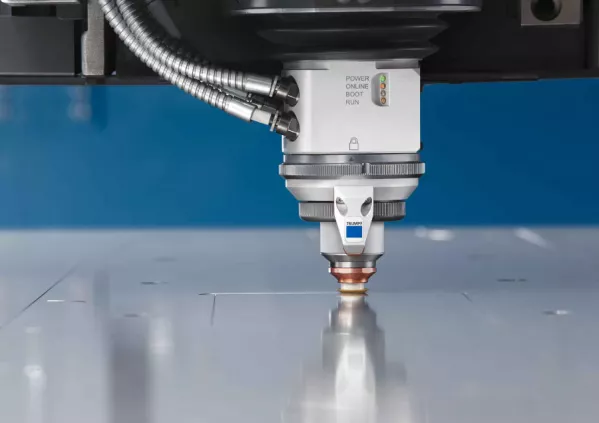

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser cutting is a heat treatment method that allows metallic and non-metallic materials of varying thicknesses to be cut with a laser that is guided, shaped and fused. When the beam hits the workpiece, the material melts or vapourises. The full power of the laser is concentrated at one point, where the greatest amount of heat is accumulated, and then the laser cuts. The laser beam does its work without touching the material. As a result, the laser does not wear out and the workpiece is free of damage or distortion.

Laser cutting is a fast and safe method of cutting materials. Of course, each laser cutting machine has its own parameters that affect the entire cutting process. The most important parameters affecting the cutting process are:

Our latest Trumpf laser cutting machine with a Fiber source and TruDisk laser power of 6 kW can handle a wide variety of cutting tasks, which you can read more about on our website under the "laser cutting" tab.

We invite contractors from Poland and abroad to continuous and close cooperation in the field of laser cutting, which is our priority service. We guarantee quick processing of orders and the highest quality of cutting. We can offer you years of experience in the field of metal forming and a modern machinery park.

For more information, please call +48 95 762 08 61 or visit us in Strzelce Krajeńskie, ul. Cmentarna 4.

We recommend our newest heat treatment method - laser cutting.