+48 95 762 08 61

Modern technologies of metal working

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

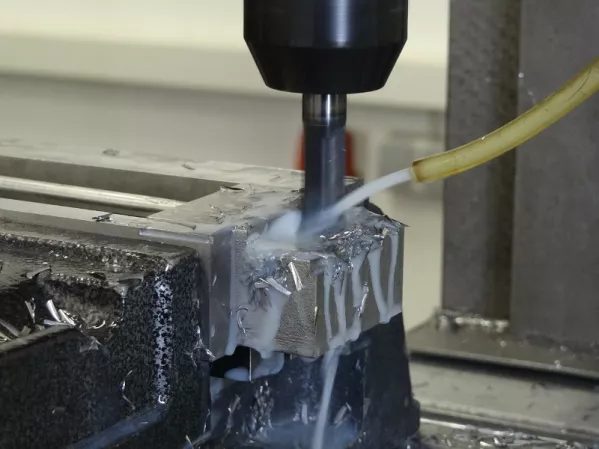

The machining process raises the temperature at the tool-material interface. For this reason, it is important that heat control is carried out using appropriate machining fluids. This is done in order, among other things, not to deform the material or overheat the cutting tools. Such fluid should have the advantage of not only absorbing heat sufficiently but also having the ability to release it quickly, obviously in order to prevent the fluid from overheating. Other important functions of processing fluids include:

Coolants used in machining are most often made by mixing emulsifying oils with water, but other types of agents such as microemulsions, machining oils and synthetic fluids are also acceptable. They are mainly in the form of a concentrate, which also contains emulsifying agents and various lubricity or corrosion protection additives. When choosing machining fluids, it is important to take into account the machining parameters, the type of machining, the machines used, but also the hardness of the water used to make the emulsion. Nowadays, environmental protection is a key issue, which is why substances that are safe for humans and the environment are used.

The use of suitable processing fluids leads to:

In our plant, we take care to control the machining fluids which, as you can see, have a great influence on the quality of the machining parameters. We are pleased that our machining centres are state-of-the-art machinery that allows us to offer high productivity, high working speeds, precision and reliability.

We encourage you to learn about our CNC milling offer on our website, and for more information, please call +48 95 762 08 61.

We care about the quality of our milling services at every stage of the process.

We look forward to working with you.