+48 95 762 08 61

Modern technologies of metal working

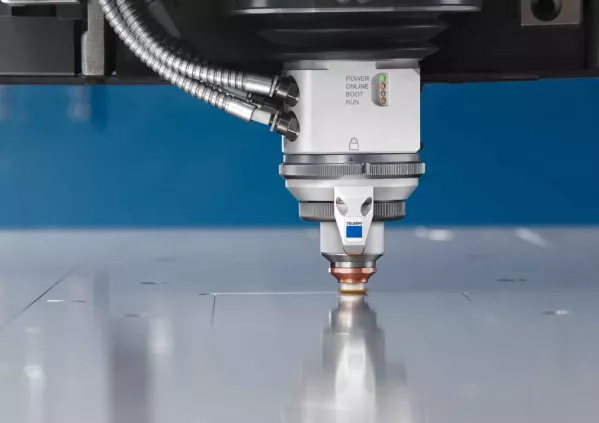

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser cutting is one of the best and most efficient methods of metalworking. Like every method, it has its pros and cons. When it comes to listing the pros of laser cutting, we can talk about a long list, but when it comes to the cons, it is short. Of course, this is only for the benefit of our factory and customer.

Among the biggest disadvantages, or downsides, of laser cutting is, of course, the cost of purchasing the laser and its accessories, as well as the training of employees. Despite the high cost of the laser, overall, laser cutting is the most efficient, versatile and precise method for processing many materials. For this reason, our plant has also invested in a state-of-the-art laser cutting machine from Trumpf with a Fiber source and 6 kW TruDisk laser power. Thanks to this machine, we are able to process orders not only from within the country, but also from abroad, mainly from Germany and other Western European countries. A novelty in our company is laser cutting of steel, which can have different surfaces, from matt to mirror-like.

We encourage companies from all over the country and abroad to familiarise themselves with our laser cutting offer on our website. For more information, please call +48 95 762 08 61. The disadvantages of laser cutting are really few, so it is worth taking advantage of such an advanced method of material processing.

We encourage permanent cooperation