+48 95 762 08 61

Modern technologies of metal working

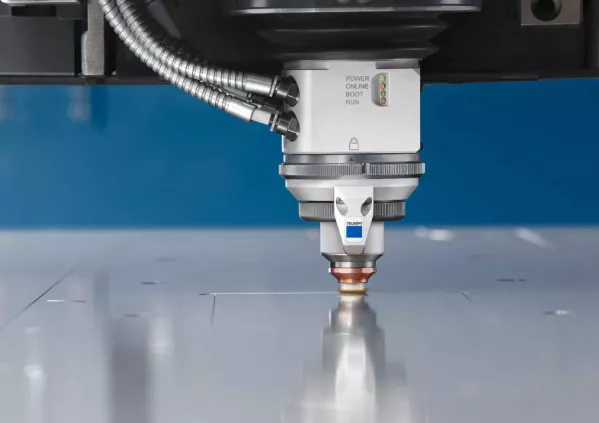

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Laser beam cutting

Laser cutting of tubes and sections

Robotic welding

Sheet metal bending

Will laser cutting dominate industrial cutting processes? This is one of many questions being asked about laser technology in the industry. Industrial cutting processes are being adapted to changing market requirements.

The versatility of laser cutting is dominant due to the possibility of processing a wide variety of materials. In addition, laser technology guarantees high cutting precision, smooth edges (no further processing) or high process efficiency. CO2 lasers have been widely popular, but are increasingly being replaced by fibre lasers. Gas (CO2) lasers are characterised by, among others, relatively low power, which significantly limits their application options. Today, fibre technology has become the standard, where it has reached the power of 6 kW fiber lasers. Such a powerful laser is perfectly capable of cutting sheets 20 mm or even 25 mm thick. But the advantages of other industrial cutting methods, such as waterjet or plasma cutting technology, cannot be overlooked.

In our company, we also use excellent fibre technology using a Trumpf laser punching machine with a Fiber source and a TruDisk laser power of 6 kW. It is a modern and fast punching machine equipped with innovative systems and technologies for 2D laser cutting of sheets with a machined sheet size of 3000 x 1500 mm.

You can read more about our laser cutting technology on our website and we shall provide additional information in person at our office in Strzelce Krajeńskie, ul. Cmentarna 4, the Lubuskie Province.